In our recent webinar and white paper, we examined the topic of flat panel displays from an imaging & calibration perspective. Among the variety of tests that utilise OEM imaging solutions in flat panel displays are tests for cosmetic flaws. These tests are a specialist area for one of our most popular OEM cameras – the VS Series.

Cosmetic Flaw Testing

With the high volume and value of flat panel displays, it is vital that manufacturers ensure that their quality control process can identify any flaws that exist within the product. Cosmetic flaws, such as small scratches or chips, that are present in the external glass or antireflection coating can be very difficult to spot with the naked eye due to the low contrast when compared with their immediate background.

Therefore, a camera used in conjunction with polarising filters can significantly exaggerate the appearance of any cosmetic flaws and consequently heighten the chances of spotting them during the quality control process. Exaggeration of the appearance of the flaws can also be achieved through using an illumination set at an oblique angle alongside a camera.

What camera to use?

Due to the low contrast of any potential flaws with their immediate background, it is advantageous to select a camera with a large bit depth and a wide number of grey levels when choosing a camera for cosmetic flaw examination. This is likely to take the shape of a camera with a cooled CCD sensor. It is also the case that any colour from the image is unlikely to be of use and therefore a mono variant of the camera would be best suited.

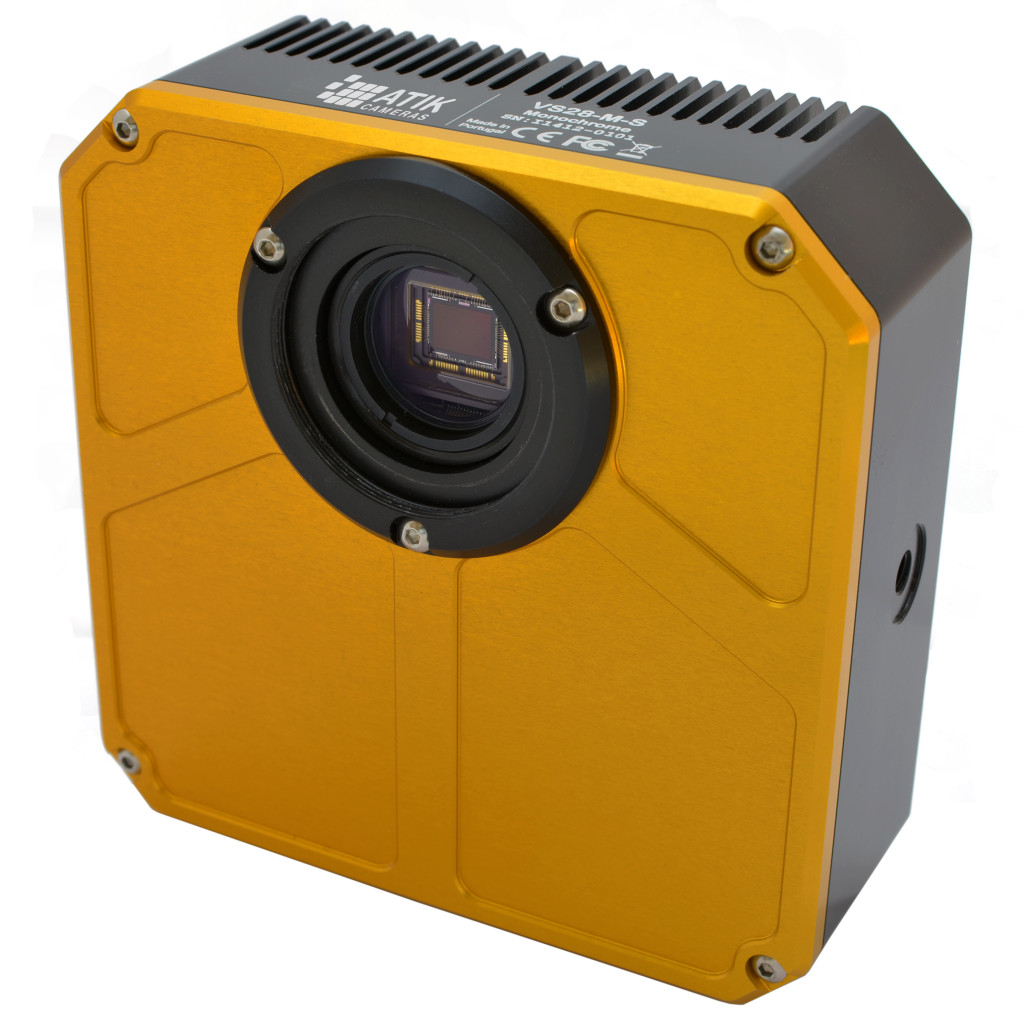

With these considerations in mind, Atik’s VS Series is ideally suited to such applications. This is because the series provides high quality images under low light conditions as a result of its advanced electronics. With headline specifications of 16 bit digitisation that provides 65,536 grey levels, this series is capable of comfortably exposing even the most minute of scratches and chips.

Additionally, this series supports a wide choice of cooled Sony CCD sensors such as the ICX285, ICX274, ICX674, ICX655, ICX694, and the ICX814. Furthermore, the use of filters to exaggerate the appearance of cosmetic flaws is easily achieved through the addition of the optional 5-position integrated filter wheel. Finally, all models in this series are available in a mono variant to perfectly satisfy the traditional requirements of imaging solutions for cosmetic flaw inspection in flat panel displays.

Learn More

It is vital to ensure that cosmetic flaws in flat panel displays are kept to a minimum and the Atik VS Series can be a major part of ensuring that this is achieved, complete our enquiry form here to see how the VS Series could help you. However, the test for cosmetic flaws is only one of the numerous tests in which our OEM imaging solutions are well placed to conduct. To learn more, download our white paper on the subject by completing the form here.